Structural characterization

Contact: Gary Chinga Carrasco

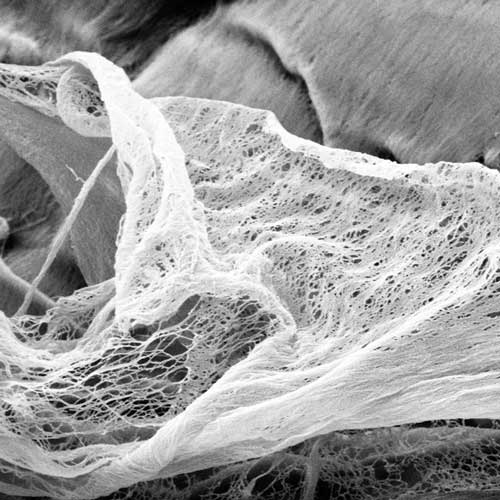

Advanced depicting techniques and analysing tools for bio-based materials

RISE PFI has developed and applied advanced depicting techniques and analysing tools for 2D and 3D characterisation of a range of bio-based materials, including nanocellulose, biochar, fibre, paper and composite structures. Our characterization methods will facilitate improvements of the final products and a broader understanding of their properties.

Selected equipment

- Scanning electron microscopy

- Ion milling system

- Scanners and high-resolution cameras

- Light microsocopy

- Laser profilometry

- Computerized image analysis

Selected methods

Fibre

| Fibre cross-sectional characteristics | PFI-method |

| Fibre external fibrillation | PFI-method |

| Fibre surface structures | PFI-method |

Paper structure

| Wiremarks | PFI-method |

| Dirt specks | PFI-method |

| Optical formation | PFI-method |

| Fibre orientation – Z-direction (splitting) | PFI-method |

| Surface structure – filler spatial distribution. | PFI-method |

Paper cross-sectional analysis

| Roughnes | PFI-method |

| Filler distribution in the z-direction | PFI-method |

| Density distribution | PFI-method |

| Fines distribution | PFI-method |

Coating structures

| Coating structure | PFI-method |

| Surface structure | PFI-method |

Dimensional stability

| Fluting | PFI-method |

| Cockling | PFI-method |

Print quality

| Cold-set print quality. | PFI-method |

| Half tone dot quality | PFI-method |

| Mottling | PFI-method |

| Picking | PFI-method |

| Ink coverage | PFI-method |

| Whiskering | PFI-method |

Novel materials

| Characterisation of nanocellulose | PFI-method |

| Fibre-reinforced composite materials | PFI-method |

Structural characteriztion

RISE PFI is part of RISE - Research Institutes of Sweden

RISE PFI is and internationally acknowledged research institute within processes and products based on lignocellulose. RISE PFI´s focus areas are Fibre technology and fibre-based products, Biorefining and Bioenergy and Biopolymers and Biocomposites.

Contact

- Høgskoleringen 6b

- NO - 7491 Trondheim

- firmapost@rise-pfi.no

- +47 73 60 50 65